Company A, a German SME with fewer than 30 employees, operates in international trade, primarily sourcing from Chinese suppliers. Their supply chain is critical to business continuity, yet they faced various disruptions due to political changes, logistics challenges, and supplier-related risks.

Their challenge was to monitor and manage supply chain risks efficiently without the resources to establish a dedicated risk department. Until now, their supply chain manager conducted manual investigations and purchased annual supplier reports, which quickly became outdated.

To enhance resilience, they turned to Golden Owl’s intelligence platform, benefiting from affordable pricing, an easy-to-use interface, and automated intelligence capabilities.

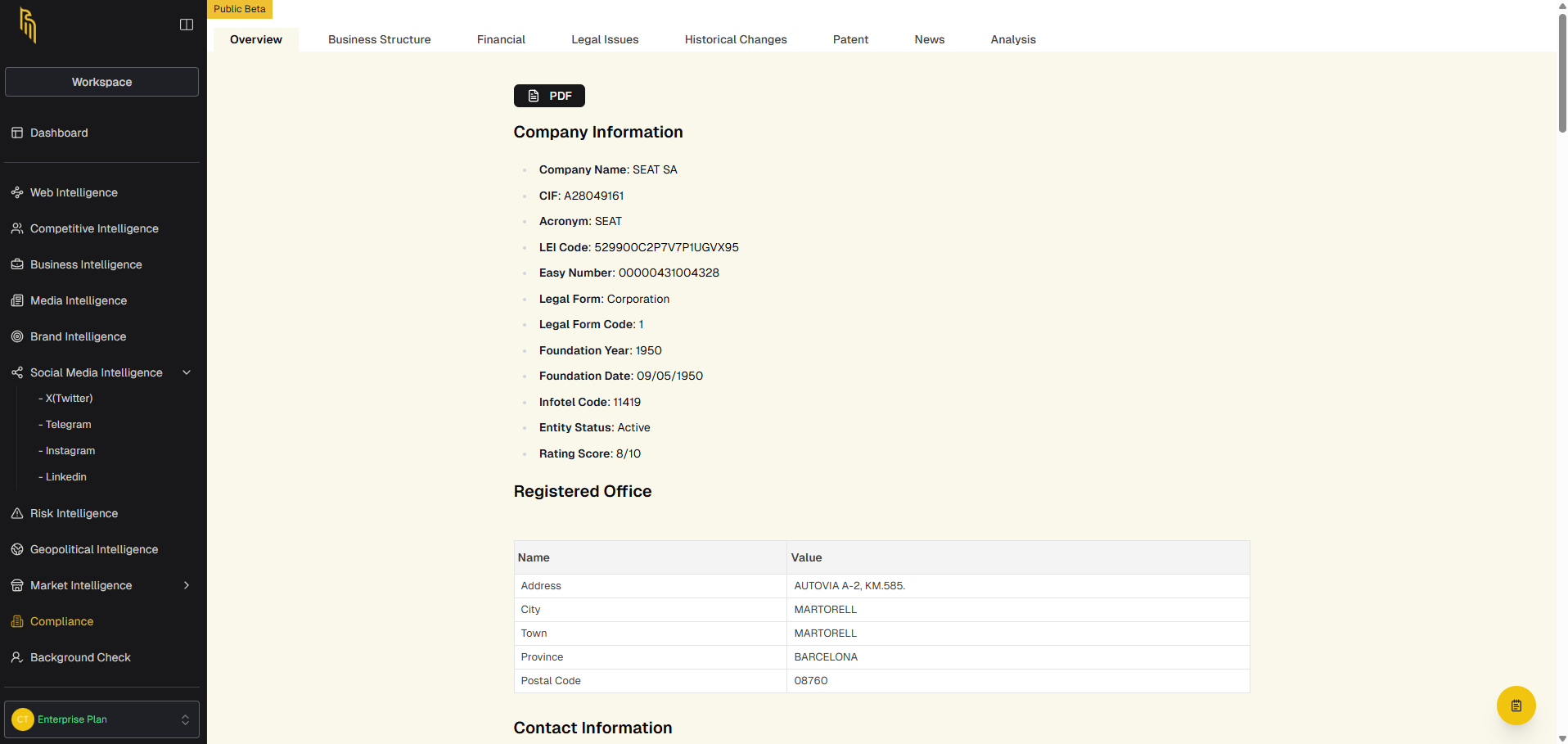

To ensure their suppliers remained reliable and compliant, they created KYB/KYC Collectors for their Chinese partners, retrieving:

Challenge: Keeping supplier compliance information up to date without relying on outdated annual reports.

Outcome: They received detailed, real-time compliance reports with far more insights than purchased reports, enabling proactive risk management.

They conducted Media Intelligence investigations on their supplier companies and key executives, retrieving:

Challenge: Accessing reliable information from Chinese media without language barriers or time-consuming manual research.

Outcome: They uncovered valuable insights on supplier reputation and risks, identifying potential issues before they escalated.

.png)

To ensure supply chain flexibility, they created Competitive Intelligence Collectors to:

Challenge: Having backup suppliers ready in case of unexpected changes or disruptions.

Outcome: They developed a list of alternative suppliers, ensuring they had contingency plans in place.

.png)

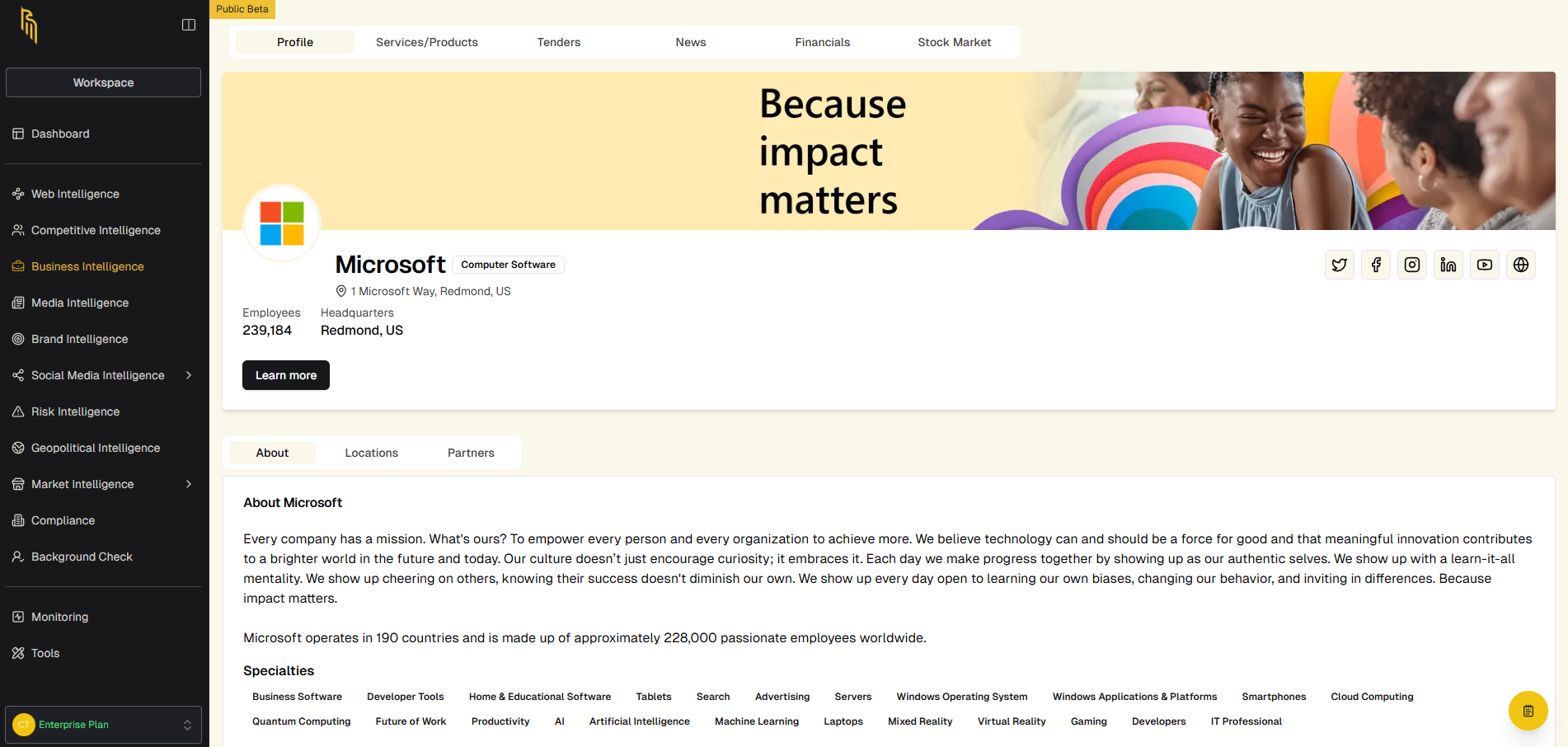

To strengthen their logistics strategy, they used Business Intelligence Collectors to analyze:

Challenge: Ensuring supply chain transparency and understanding how logistics partners handle risks.

Outcome: They gained deep insights into logistics providers, allowing them to optimize transport strategies and anticipate possible bottlenecks.

Since external factors play a significant role in supply chain stability, they used Geopolitical Intelligence Collectors to:

Challenge: Staying ahead of political and regulatory changes that could impact the supply chain.

Outcome: They received timely geopolitical intelligence, enabling them to proactively adapt to potential disruptions.

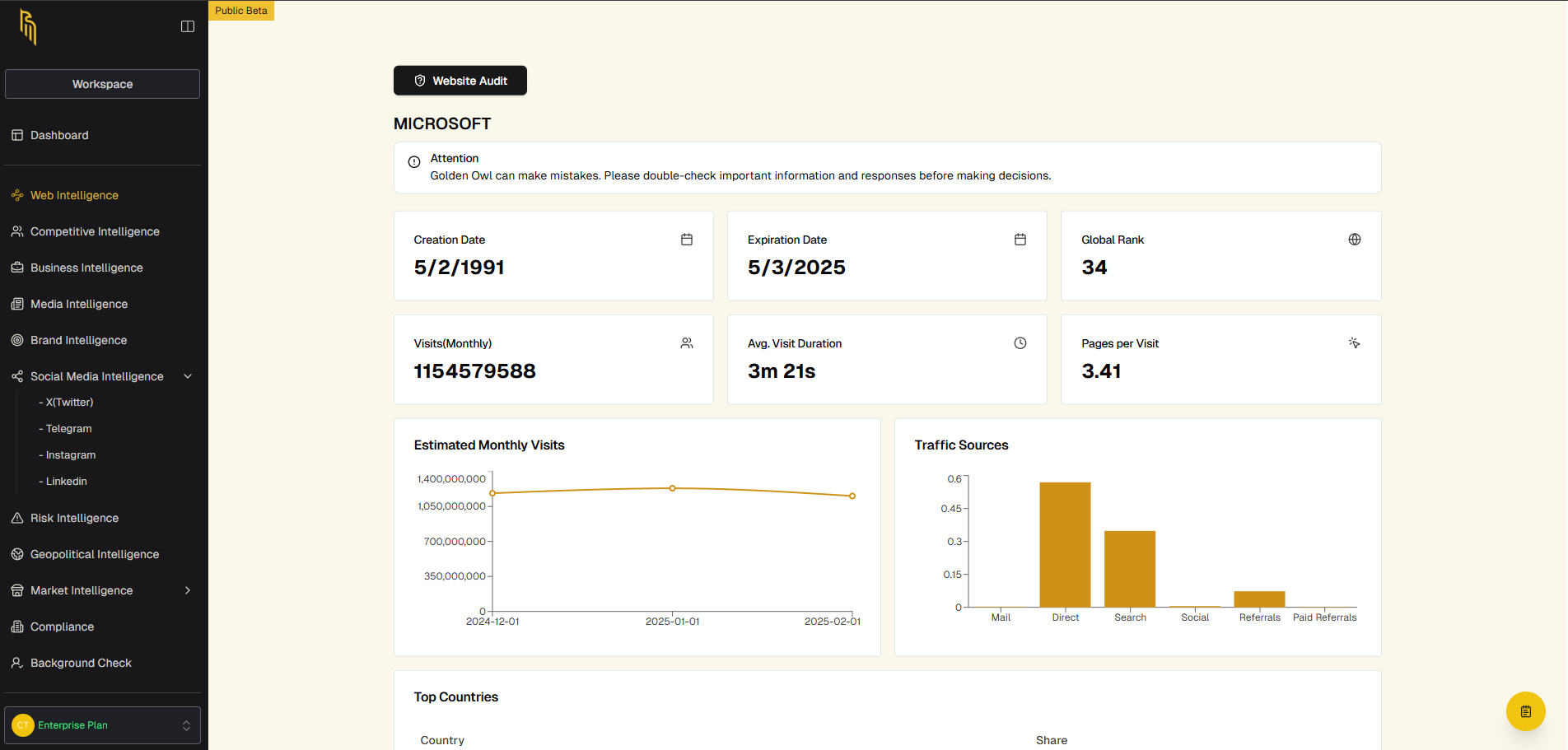

To ensure continuous supplier evaluation, they deployed Web Intelligence Collectors, which provided:

Challenge: Identifying hidden risks, unreported business changes, and scale fluctuations in their supply chain.

Outcome: They gained deep insights beyond traditional reports, allowing early detection of shifts in supplier activity and potential vulnerabilities.

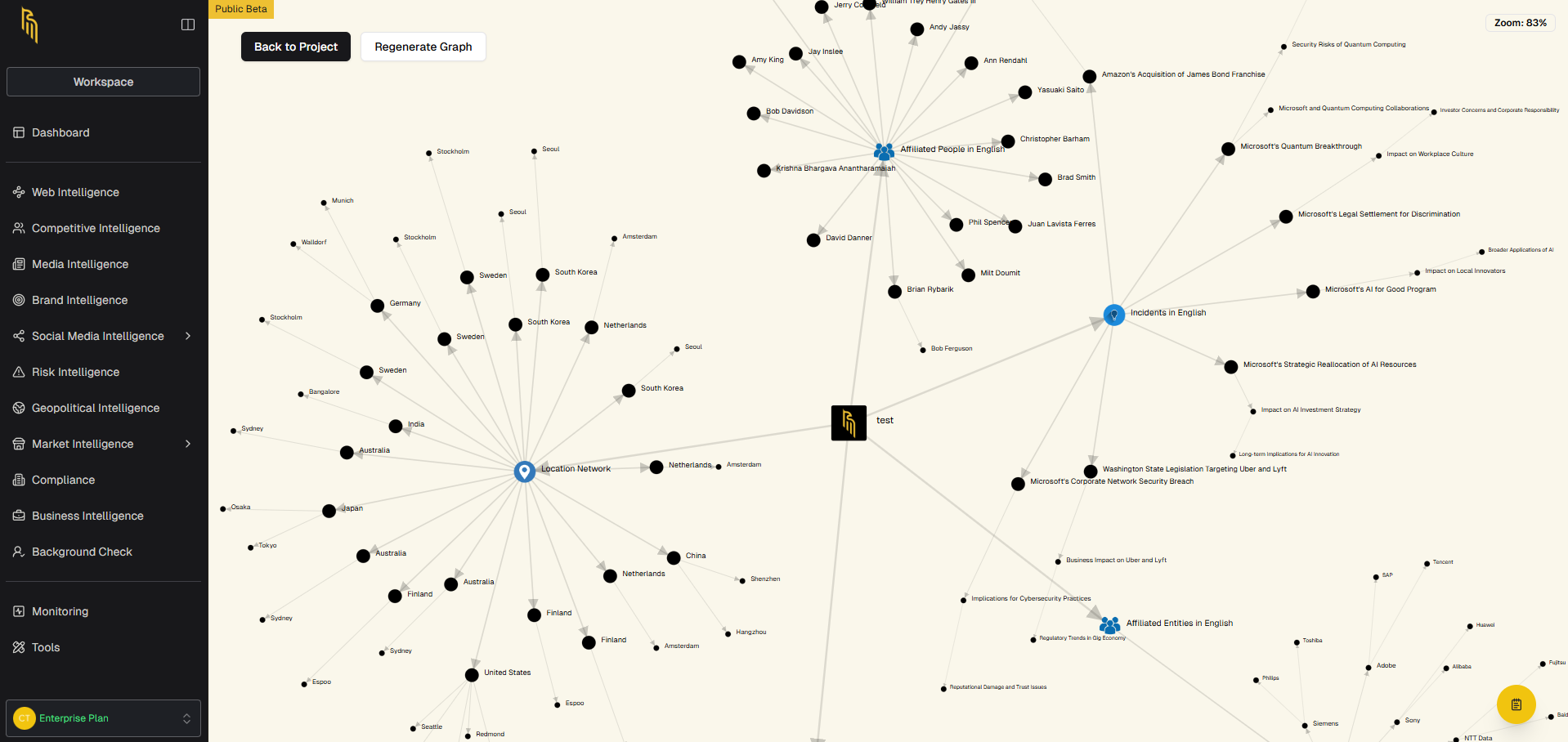

To visualize complex supply chain relationships, they created projects for each partner, integrating:

Challenge: Seeing the full picture of their supply chain and understanding interdependencies between suppliers, competitors, and logistics providers.

Outcome: They uncovered hidden risks and valuable intelligence, allowing better decision-making based on a full supply chain analysis.

To stay ahead of risks, they created automated monitoring for each supplier and logistics partner, which:

Challenge: Keeping track of supply chain risks continuously without manual effort.

Outcome: They set up real-time monitoring, ensuring automatic alerts on potential disruptions, making their supply chain more resilient and predictable.

In just one and a half hours, the company accomplished what previously took weeks of manual research, achieving:

By integrating Golden Owl’s intelligence tools, the company now makes informed, proactive decisions, reducing supply chain uncertainties and improving operational resilience.

By using Golden Owl’s intelligence platform, the company was able to:

Golden Owl proved to be the perfect match for their needs, acting as an intelligent advisor that provided critical insights on demand, without the need for a large internal risk team.